本文是一篇物流论文,笔者认为加纳采矿业的供应链管理者面临着不断的压力,他们必须同时制定出相对高效和以客户为中心的战略和计划,并找到最具创新性的方法来降低成本,进而利用增长。除此之外,管理者必须能够利用其利基市场和商业经济环境中的机会。

CHAPTER ONE INTRODUCTION

1.1 Research Background and Significance

1.1.1 Background of the Research

Firms in the mining industry especially for developing countries lack the appropriate models to optimize their logistic operations, mainly because they tend to focus more on procuring modernized equipment and technologies to carry out the already complex processes of the mining industry. For instance, third party logistics service providers sometimes find it a hurdle to forecast their supply chains due to supply chain risk and uncertainty (Min, 2015). For this reason, most mining companies outsource their logistics and transport operations to third party (3PL) logistics operators; whose profit mindedness stifle the integrated efficiency, optimal cost and profitability targets of mining companies. The quest to meet the dynamic and myriad service targets of clients coupled with the need to remain in business, have augmented the level of competition in the logistics services industry. Hut and Speh (2012) attributed the complexity of the transportation business to the unpredictable increase in business on some trade lanes and the laws of the importing country. By necessary implication, transportation careers and service providers now have to compete openly and aggressively against new entrant, existing carriers and competition from other modes of transport (Monczka et al., 2015).

In as much as the mining industry contributes hugely to economic and social growth, its operations are characterized by complex supply chain processes that are relatively capital and cost intensive, and technologically sophisticated to manage. Consequently, the rationale for this study is to analyze the logistics and supply chain operations of mining companies in Ghana, identify the challenges and inefficiencies associated with these operations and their underlying causes, and recommend logistics and supply chain management design, modelling and analysis tools to optimize operations of Ghana’s mining industry and ensure increasing profitability and cost efficiencies. In the words of Domingues et al. (2017), the mining sector is implicitly complex in nature, involving major hazards and risk factors, vulnerable conditions, socioeconomic impacts, and resource nationalism.

1.2 Problem Statement

Ghana is so rich in terms of minerals such as bauxite, gold and among others however, there is lack of infrastructure to extract these minerals and export them in large quantity. One of the most challenging situations managers encounter is how to best use limited resources in the most optimal way possible; thus, minimizing cost whilst maximizing profit and not compromising the quality of service. Mismanagement of resources in the transportation of products can result in in the bankruptcy of a company whose transportation cost contributes a significant percentage of then overall operating cost. This shortcoming is either due to a truck breakdown or a halted mining activity at the mining sites. Also, when trucks breakdown in transit to some or all mining sites, it takes about 2 days or more for the product to be delivered to their required destination ports and that means no work done for such trucks during the breakdown periods.

CHAPTER TWO LITERATURE REVIEW

2.1 Definition of Concepts

Key concepts identified in this project include; Logistics Management, Supply Chain Management, Strategy, Efficiency, Mining. These terms have been explained and defined below from the viewpoint of the purpose of this research, and thus should be interpreted and understood as such.

Logistics Management: Logistics management in this study represents the methods and strategies used by mining companies to plan, control, and store information about goods from mine to destination hence meeting customer demands.

Supply Chain Management: This describes the activity of managing the flow of goods from raw material to final product while checking each stage to add value and maximize profits. Strategy: In this research, strategy simply means the set of designed plans geared towards achieving an efficient logistics and supply chain operation. This becomes the benchmark for measuring performance.

Efficiency: This refers to the quality of handling resources in managing logistics and supply chain in the mining industry to achieve the benchmark.

2.2 Global Overview of the Mining Industry.

2.2.1 Revenue trends and growth pattern

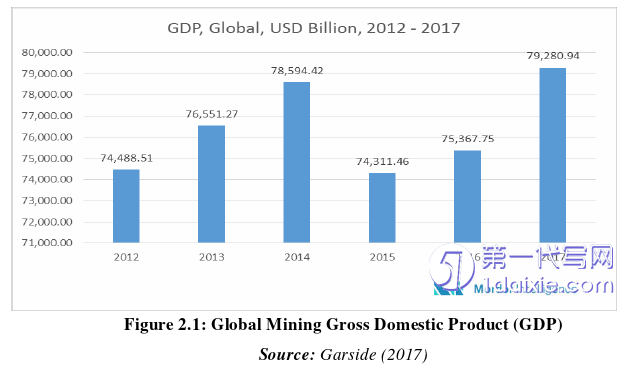

The global mining industry has, been described as one of the largest with its most powerful and influential companies scattered all over both developed and developing countries of the world (Rugman,2005). The industry is interconnected as natural resources are distributed across different jurisdictions of the world (Daniel Shapiro, Bonita Russel, and Leyland Pitt,2007); it is therefore important for research to focus on exploring and how to lump all these companies in the global mining sector possibly through an internet of things (IOT) approach to ensure mutual benefits. According to recent mining statistics and facts, the top 40 organizations which are the main movers and shakers of the whole industry made a revenue of more than 600 billion US dollars in 2017 and has been on a rollercoaster ride till date; hence the mining industry is a very essential pivot of the world’s economic growth (Garside, 2017) (see figure 2.1). It is however critical to note that, this revenue in 2017 is 10% less than the previous year. Garside (2017) also reported that, world top five mining companies in terms of revenue in 2018 were UK-based. United states have also been phenomenal as it has created 621,00 jobs with a gross output of 288 billion US dollars as of 2017. Further predictions were made beyond 2019 as shown in figure 2.2.

CHAPTER THREE METHODOLOGY OF THE STUDY ............................ 24

3.1 Project Philosophy ........................................... 24

3.2 Approach of Research ................................ 26

CHAPTER FOUR PROJECT ANALYSIS AND FINDINGS.......................... 31

4.1 Introduction ....................................... 31

4.2 Analyzing The Logistics Management Operations of Firms in Ghana’s Mining Industry ......31

CHAPTER FIVE A STRATEGIC MODEL FOR EFFICIENT AND OPTIMAL LOGISTICS MANAGEMENT PERFORMANCE OF MINING FIRMS IN GHANA .... 40

5.1 The Logistics Managemennt Efficiency and The Competitive Position of Firms in Ghana’s Mining Industry .............................. 40

5.2 Recommended Optimal Logistics Management Efficiency for Mining Firms in Ghana .......................................... 41

CHAPTER FIVE A STRATEGIC MODEL FOR EFFICIENT AND OPTIMAL LOGISTICS MANAGEMENT PERFORMANCE OF MINING FIRMS IN GHANA

5.1 The Logistics Managemennt Efficiency and The Competitive Position of Firms in Ghana’s Mining Industry

The logistics and supply chain management function of Ghana’s mining industry is doing well and organizations are not at a much of a competitive disadvantage. Being ranked the 10th largest producer of gold and generating the revenues stated above suggests there is an enabling environment to thrive globally. But to achieve this global competitiveness, the supply chain must be analyzed to fish out inefficiencies and replace them with value- creating factors or components. This probably why Fawcett et al. (2014) points out that, the more companies become aware of best practices in supply chain, the more they try to enhance supplier relationships to create overall value and get competitive advantage. Ghana does international trade by exporting products from mining and this according Porter and Tanner (2012) is a basis for competitive advantage.

The industry looks open especially for large-scale mining companies like Ghana bauxite company, Newmont gold Ghana limited, Gold fields Ghana limited and Anglo gold Ashanti. Hence there is a need to focus more on analyzing the entire supply chain to identify factors that create value and enhance it while eliminating factors that breaks the supply chain. For example, while transporting gold from the mines to factory for production, lead time is very critical hence maintenance of trucks must be a priority. In addressing issues of bad roads, the critical path method can be used to determine which route is ideal to deliver goods just in time. Companies can also engage in corporate social responsibility activities like constructing roads which will not only develop the community but also optimize supply chain: benefits are dyadic.

CHAPTER SIX SUMMARY OF FINDINGS, RECOMMENDATION AND CONCLUSION

6.1 Summary of Findings and Conclusion

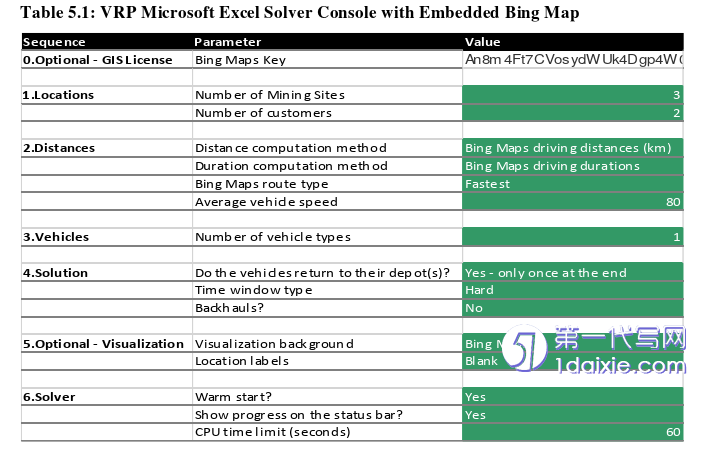

With focus on the logistics and supply chain operations of firms in Ghana’s mining industry through a VRP spectacle as shown in the secondary data, this study intimates the following significant findings following critical data analysis of the logistics challenges of mining firms in Ghana with recommendations on how to enhance their logistics, transport and operational efficiency. It cannot be contested that, mining operations hold great economic importance across all countries in the world especially developing countries like Ghana (Kusi-Sarpong et al.,2014). Newmont Ghana Gold limited, Anglo Gold Ashanti, and Gold fields limited are the key players used as a basis for analysis in this study. It is found that Newmont Gold Ghana Limited sources all its raw materials locally with chain fencing link and barbed wire being the most locally sourced. In a bid to increase local supply, mining firms in Ghana generally include catering, transportation, healthcare, control systems, specialized services, mine construction and component manufacturers as categories of suppliers’ but major activities are centered on specialized services and component manufacturers with frequencies and percentages of 48,30.4% and 25,15.8% respectively. While Newmont Gold Ghana limited prioritizes specialized services, it is number three on the list for suppliers while catering hits local supplier topmost priority with 42%.

reference(omitted)